The Challenge

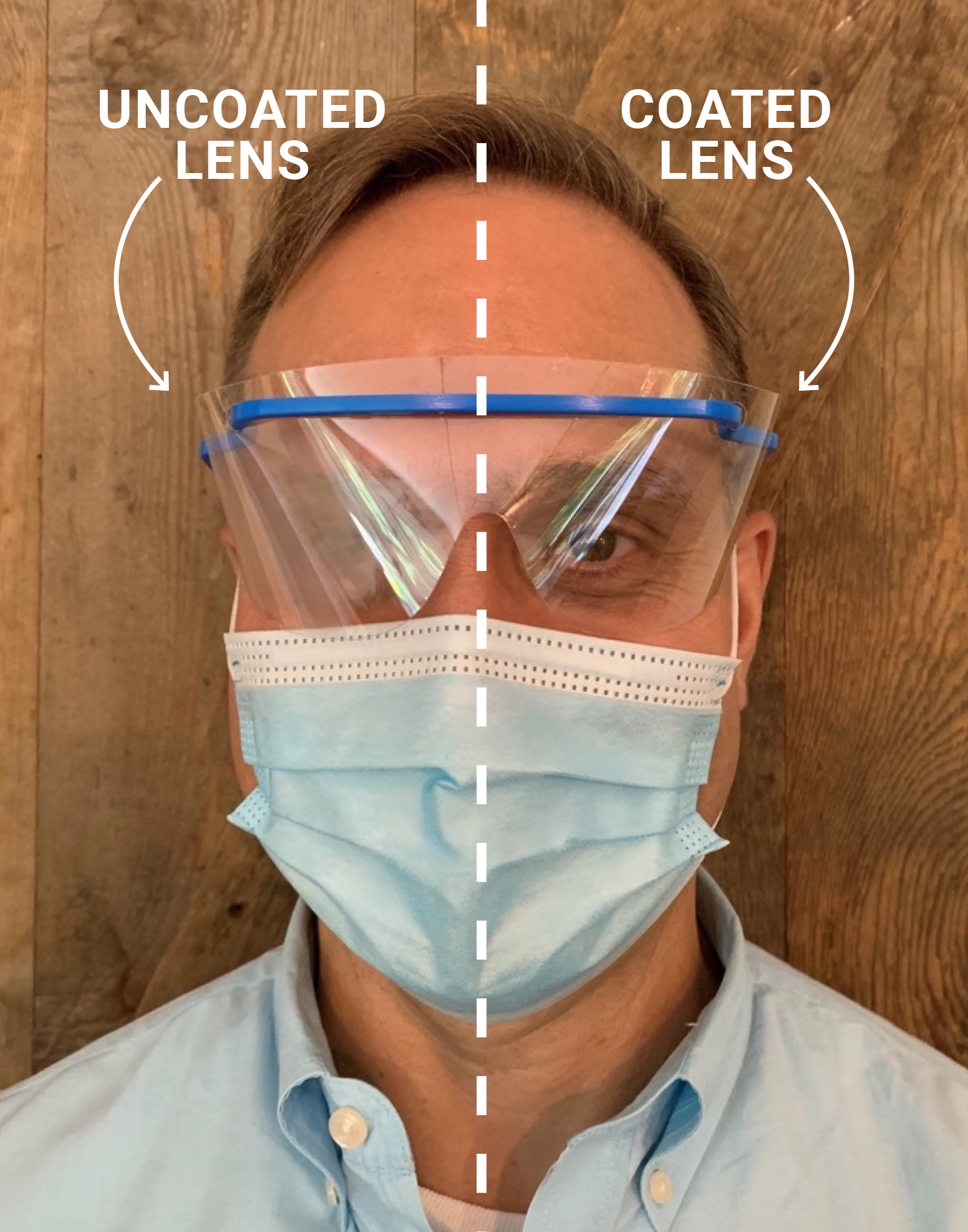

During the COVID-19 pandemic, protective eyewear became a universal requirement to help protect healthcare workers from infection. However, wearing protective eyewear with a mask quickly highlighted a major issue – lens fogging.

The Solution

A novel solution based on a unique polymer with anti-fogging properties was identified and applied to standard protective eyewear lenses. In a randomized clinical trial, we found that this coating resulted in a significant decrease in lens fogging, as well as a significantly improved user experience and perceived reduction in potential patient safety events.

Project Partners—

Kraton Corporation

Services

Practical Implementation Support, Measurement & Impact

Year

2020

Specials Thanks to—

Ali S. Raja, MD, MPH, MBA; Justin D. Margolin, BS; Hui Zheng, PhD

Defining the Challenge

During the COVID-19 pandemic, leading health agencies such as the Centers for Disease Control and Prevention and the Occupational Safety and Health Administration recommended use of protective eyewear to protect healthcare workers from infection. However, frontline providers experienced the frequent problem of fogging of their protective eyewear. More than just an annoyance, this fogging could impact patient care, provider safety and experience, and adherence to proper wear and usage. This issue has been highlighted in the literature, but few offer practical solutions.

Co-Designing a Solution

Flexible and curious to the unexpected paths a project could take, the Springboard team discussed a possible sanitary coating for the Hexapod booth’s surfaces (see Hexapod case study) in the spring of 2020. In discussions regarding these coatings, a hydrophilic polymer in early stages of commercialization was identified within an external company, Kraton Corporation, a global leader in polymer innovation and biobased chemicals. In our discussions, we recognized this polymer had anti-fogging properties and saw an opportunity for using it in a novel way on glasses or goggles in healthcare settings. With urgent demand for this type of product in hospital settings across the U.S. and the world, we helped coordinate a global mobilization during the height of the COVID pandemic. The team arranged for transferring the anti-fog polymeric film produced in India to a factory in Taiwan where they halted their regular production to die cut this film into standard lens shapes that could subsequently be used for protective eyewear. These lenses were then applied to standard frames upon arrival in Boston.

A common frustration for frontline workers (and glasses-wearers generally) – fogging PPE eyewear – during the Covid-19 pandemic.

By the Numbers—

Coated

eyewear

reduced

fogging by

50%

compared to

uncoated eyewear

For providers and staff

wearing surgical masks,

coated eyewear reduced

negative impacts to care by over

80%

compared to

uncoated eyewear

Coated eyewear

caused providers

and staff to

touch their faces

50%

as much as

uncoated eyewear

Impact

Although there were other fog-resistant protective eyewear on the market, most of these products had unfounded claims regarding their efficacy and none had been tested in a clinical environment. Springboard Studio designed a first of its kind clinical trial to test the anti-fogging properties of this polymer in a real-world clinical setting. The blinded, randomized-controlled cross-over clinical trial included nearly 50 front-line healthcare providers (physicians, physician assistants, nurse practitioners, and registered nurses) in the high-throughput emergency room at Massachusetts General Hospital (MGH). Participants wore both a coated (anti-fog) and standard, uncoated PPE eyewear. The study found that there was a significant difference in fogging between the coated and uncoated eyewear with participants reporting that the uncoated eyewear fogged twice as frequently. Additionally, healthcare providers wearing the eyewear with a surgical facemask perceived that the uncoated eyewear would significantly impact clinical care negatively at approximately 5 times the rate compared to the coated lenses. Similarly, participants reported that fogging of the uncoated eyewear limited their ability to perform patient-centric tasks significantly more frequently than the coated eyewear. Fogging of the uncoated eyewear caused participants to touch their face nearly twice as frequently compared to the coated eyewear. Importantly, users did not report any significant difference in distortion or limitation of one’s vision due to the lens coating. This study, which was published in the peer-reviewed British Medical Journal (BMJ Innovations), validated the efficacy of the antifog lens coating, as well as highlighted the positive impact on end-user experience and perceived ability to safely care for patients.

As Kraton further tested and refined their solution to deliver world-class anti-fogging performance, the MGB Springboard Studio team has continued to work with them in an effort to provide healthcare professionals with exceptional clarity during essential procedures requiring protective eyewear. In fact, based on recommendations coming from our study at MGH, Kraton has improved and re-defined anti-fog performance to the point where a new standard is now being proposed for disposable eyewear in order to insure performance integrity within the industry.

Through this developmental process with Kraton, the BiaXam™ product referred to in the BMJ Innovations article has been rebranded as Nexar™ Anti-Fog, and now appears to be distinctively positioned to redefine protective eyewear standards in today’s healthcare market.

Learn more at http://nexar-antifog.com/

With the uncoated and coated lenses side-by-side, this sample reveals the efficacy of the polymer coating in reducing fogging.

Learn More—